|

| New NAS, where I keep (among other things) all the videos I post here! |

I jumped ahead to section 31 so that I could match-drill the top skins to the upper fuselage side channels and machine-countersink those before priming or riveting the side skins, to avoid interference.

This section starts with cutting and fabricating a few different angles/spacers:

|

| Fabricated angles and spacer for the subpanel |

We then had to bent the lower part of the panel:

|

| Bending the bottom flange of the subpanel center section |

We put it all together and final-drilled all the holes:

|

| Final-drilled subpanel |

|

| Subpanel clecoed in place |

|

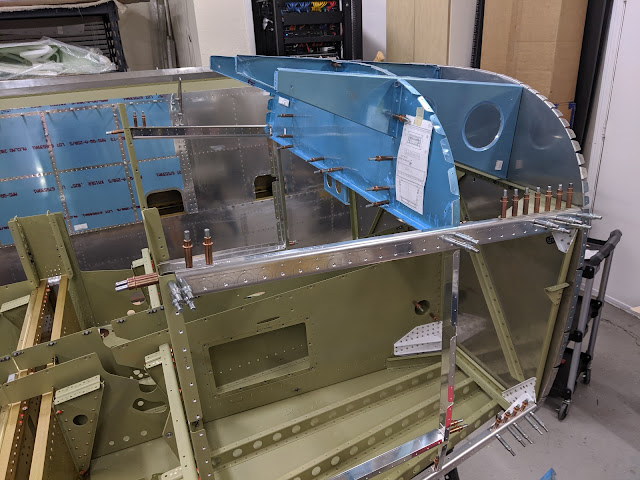

| Subpanel and top skin clecoed in place |

The hand hold doublers require some forming to lay flat against the top skin:

|

| Forming the hand-hold doublers onto the curved top skin |

For the panel support angle, I used a center line on the spacer to keep it centered, then match-drilled the holes:

|

| Aligned centerline on the panel support angle spacer, ready to match-drill |

|

| Match-drilled panel support angle |

These steps were more than sufficient to be able to machine-countersink the upper fuselage channels, so I stopped at that - I'll probably get back to it much later when I work on the panel.

Time lapse:

Total upper forward fuselage time: 11.3h

No comments:

Post a Comment