We removed the cabin cover for the last time to finish it up.

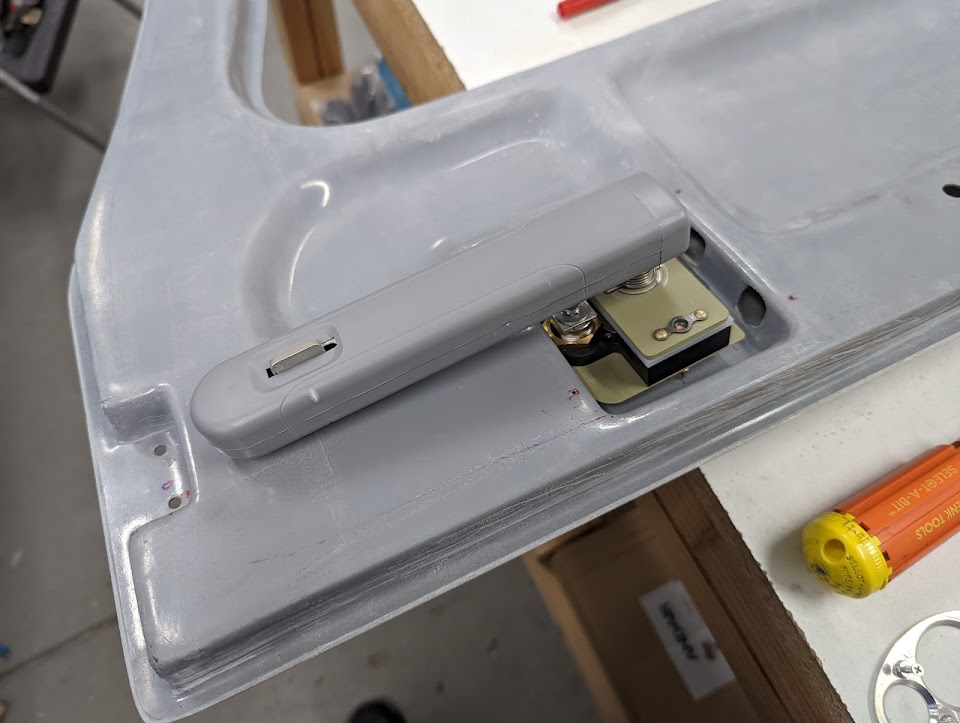

There was a pretty big gap between the cabin cover and the overhead console (about 1/4") - I sanded the cabin cover surface a bunch to reduce it, but it became clear that there was no way I was going to close the gap fully without making the fiberglass pretty thin (or getting to the foam core), so instead we built up a "shim" down from the cabin cover to meet the console:

|

| Gap between the cabin cover and overhead console |

|

| Laying up fiberglass shim for the overhead console |

|

| Overhead console in place to form shim |

|

| Overhead console shim after curing |

|

| No more gap between the cabin cover and overhead console |

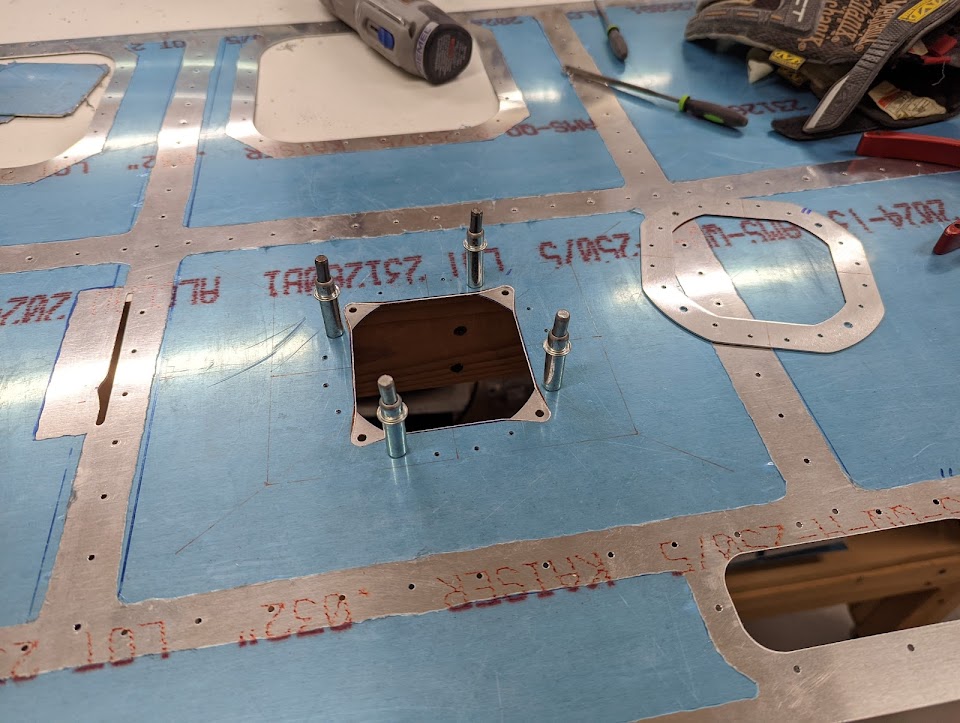

With that, I finished drilling the overhead console to attach it (when we previously detected the gap, we had only made a couple of holes - just enough to keep it in place but not enough for the attachment later):

|

| Overhead console clecoed in place |

I also made holes for running wires between the console and the switch pod:

|

| Wiring holes on the overhead console |

|

| Wiring holes with the switch pod in place |

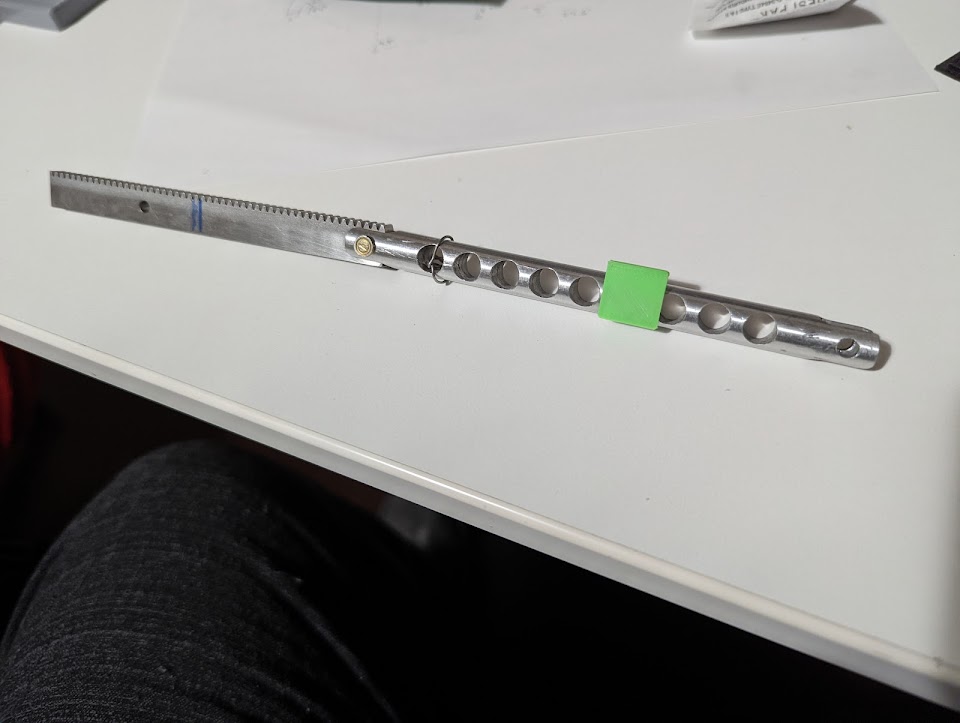

I also attached the ventilation flanges for the overhead console, and riveted the baggage bulkhead channel to the top bulkhead - this may make it a bit harder to rivet the tailcone top skin later, but I didn't really have a choice due to the ordering of attachments:

|

| Overhead ventilation flanges riveted in place |

Finally, I started sanding the uncovered parts of the cabin cover, but that's one large exercise in patience, so there's a lot more to do there.

Time lapse:

Total cabin cover rivets: 64

Total cabin cover time: 77h